KITZ电动蝶阀

The World’s Loading Valve Manufacturer

The Brand of Reliability

高质量名牌阀厂产品的象征

闻名世界的综合阀门生产企业

KITZ,创业于1951年,至今,已成为世界屈指可数的综合阀门厂家之一。KITZ不仅生

产一般设备用阀门以及各种工业成套设备用阀门,还生产各种自动操作,测试设备用阀门。

KITZ在全球拥有数十家工厂,在这些工厂里,从铸造,锻造加工到组装,都是在本公司

严格的质量管理下进行系列化生产。另外,KITZ的产品在出厂时,均根据本公司制定的“质

量保证条例”进行严格检查,因此得到了世界各地用户的好评,被评为“高质量的阀门”。

本产品目录中介绍的各种阀门,都是从“建筑设备管道配线”用阀门中精选出的产品。除

此之外,还备有许多适用于其他领域的各种阀门,请直接向本公司或代理店咨询。

KITZ Corporation, a leader in the flow control industry, produces an extensive range

of Valves and auxiliary equipment. Since its foundation in 1951, KITZ has dedicated all its

resources to providing top quality products for public and private utility services, heavy duty

industrial applications and sophisticated instrumentation systems.

KITZ Corporation currently operates for domestic and for overseas Valve plants. All

KITZ plants incorporate KITZ’ unique integrated production system. With the KITZ system,

constantly updated facilities for material casting and forging, component machining, and

product.

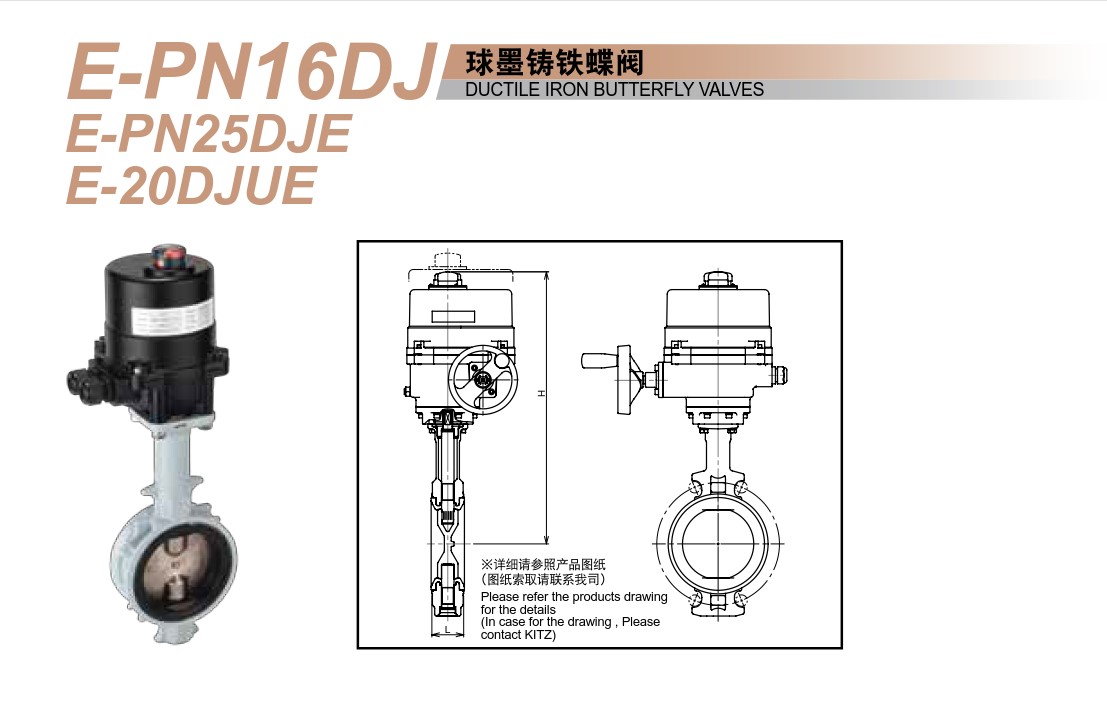

①驱动装置 Actuator

E……………Electric Actuators

②压力等级 Class

PN16………………........PN16

PN25………………........PN25

10……………….............10K

20……………….............20K

③阀门类型 Valve Type

DJ…………………球墨铸铁蝶阀

Ductile Iron Butterfly Valve

XJ…………………铝合金蝶阀

Aluminum Butterfly Valve

④连接方式 End Connection

无None…………….对夹式 Wafer

L……………………凸耳式 Lugged

⑤阀板材质 Disc Material

无None…………….球墨铸铁 Ductile Iron+ 镀镍 ENP

U…………………...304不锈钢 304S.S.

M…………………...316不锈钢 316S.S.

⑥阀座材质 Seat Material

无None…………….丁腈橡胶 NBR

E…………………...三元乙丙橡胶 EPDM

⑦公称直径 Nominal Diameter

产品编码 Product Coding

E - PN16 DJ L U E 80

1 2 3 4 5 6 7

环境温度、湿度\Ambient Temperature And Humidity :-25℃~+70℃ , <90%(25 ℃)

● 工作环境\Service Environment:不含有强腐蚀、易燃、易爆的介质\Without Any High Corrosion And Explosion Medium

● 工作时间\Working Time:KZEB1/KZEB2/KZEB3为S1工作制,其他S2工作制,额定工作时间为30min

KZEB1/KZEB2/KZEB3 Is S1 Standard , The Others Are S2 Standard,

Rated Working Time Is 30min

● 防护等级\Protection Class:IP67

● 绝缘等级\Insulation Class:Class F

● 调节信号\Modulating Signal:4~20mA

● 内部防结露\Moisture Prevent:配置防潮电阻\Adopting Heating Resistance

注意事项

警 告

● 使用样本中介绍的执行机构前,请仔细阅读本操作手册,在完全

理解后按照本手册进行操作。

● 小心搬运本产品以免脱落掉在地上。应避免任何机械碰撞。

● 应在无尘,低湿度和通风良好的室内保存本产品。

● 安装前请勿拿下保护罩。

● 禁止重压或踩踏本产品,以免损坏或造成人身伤害。

● 阀门安装时,请留出足够的空间以便手动操作或取下外罩。

● 在执行机构工作时,对暴露于日光下或雨水中的部位应采取相应

的防护措施,应该使用隔热板阻挡执行机构周围的发热设备。

● 采取相应的措施避免由于可预料到的原因如:含盐空气,雪或冰

冻造成的损坏。

● 避免将阀门和执行机构安装在由水泵或引擎之类设备引起震动的

地方。

● 安装前,须清洗连接管,除去沙子,灰尘或焊渣等杂物。

● 在紧固螺纹连接阀门时,请将工具作用于阀门与管线邻近端进行

紧固。

● 安装法兰阀时,以星形顺序交替拧紧螺栓以便将阀门正确紧固在

管线上。

● 禁止将执行机构朝下安装。

● 管道必须冲洗干净以除去所有杂物。

● 如果在水管中用铸铁或铸钢阀门,应谨防生锈以免损坏阀门部件

导致不能正常工作或发生意外。特别注意阀门的选型和防锈。

● 请根据电路图正确连接线路。

● 连接电线时一定要使用接线端子进行连接。

● 线路连接完成后,进行2次以上的绝缘测试以确保绝缘性。

● 确保机箱用O型圈之类材料密封,以防止灰尘和水进入。

● 禁止用一个开关同时操作两台或者两台以上的执行机构,且禁止

用一个 开关同时操作其他的电器设备。

● 确保加热器一直处于工作状态以防止执行机构产生冷凝水而出现

故障。

● 确保手动操作时电源断开。

● 阀门的开闭动作间隔时间应为1-2秒,否则可能导致故障。

● 不允许任何未经授权的改装,这样会引致故障或事故。因使用不

当、自行改造及不可抗力量导致的故障或事故,本公司概不负责。

● 请参照本公司样本获取更多阀门信息。

Ensure to read and follow instructions of operation manual

when handling the actuator introduced in this catalog.

● Handle the product carefully so that it may not fall or drop on

the ground.

Any extraordinary mechanical impact should be avoided.

● Indoor storage of the product in a dust-free, low humidity and

well-ventilated place is recommended.

● DO NOT remove protective cover until installation.

● DO NOT apply excessive load or step on the product, which

may damage the product or cause personal injury.

● Allow sufficient room formanual operation or the removal of the

actuator cover, when the valve is installed in the pipeline.

● Where the actuatoris exposed to sunlight or rainwater while in

service, use appropriate protection for trouble-free operation.

Also use insulation boards for heat generated from the

equipment around theactuator.

● Take some appropriate measures, if the possibilities of damage

by briny atmosphere, snow or freezing are expected.

● Avoid installing the valve where the actuator may be hampered

by vibration caused by equipment such as pumps or engines.

● Before installation, the connecting pipes should be cleaned to

remove any foreign objects such as sand, dust or welding

spatters.

● When threaded valves are screwed into pipes, apply a spanner

to the ends of valves on the side of the connecting pipe being

inserted.

● For flanged valves, alternately tighten bolts of the endflanges is

a star pattern to ensure to fasten the flanges properly.

● The actuator should not be mounted downward in any piping

orientation.

The pipeline should be flushed to remove foreign particles from

pipes.

● If cast iron or cast carbon steel valves are used in the water

line, be aware that rust may develop in the valves, which may

damage the ball seats, leading to operation failure. Pay extra

attention on valve selection and protection from rust.

● Connect cables correctly in accordance with the circuit diagram.

● Ensure to use a terminal base when connecting cables.

● After connecting cables, conduct an insulation resistance test

to ensure its insulation.

● Ensure the housing is securely sealed with such sealing materials

as O-ringsto prevent dust or water from entering the housing.

● DO NOT try to operate two or more actuators at the same time

with only one operation switch. Other electrical equipment

should not also beoperatedat the same time with one operation

switch.

● Ensure the space heater to be activated all the time to keep the

inside of the actuator warm for the prevention of due condensation,

which may result in operational malfunction.

● Ensure the actuator is powered off, when it is used for manual

operation.

● Place at least one-second interval, When the direction ofoperation

is reversed. Failure to follow this instruction may result in operation

malfunction.

● DO NOT make any unauthorized modifications. Such modifications

mayresult in causing a troubled operation or accidents. We

shall not be responsible for any troubles or accidents caused by

improper use of the products.

● Refer to our catalogs for more details on valve information.

警 告

● 本产品不防爆,禁止在易燃和腐蚀性气体环境下使用,不允许用于易燃流体

● 禁止在通电时拆卸本产品。

● 阀门动作时,禁止将手指和其他异物放入阀门内部。

WARNING

● This product is not designed for explosion-proof DONOT use it in any

inflammable or corrosive gaseous environment. Also DO NOT use it

for handling inflammable fluid.

● DO NOT disassemble the actuator while the unit is being energized.

● DO NOT put your fingers or insert any foreign objects within the valve

core before or during valve operation.